-

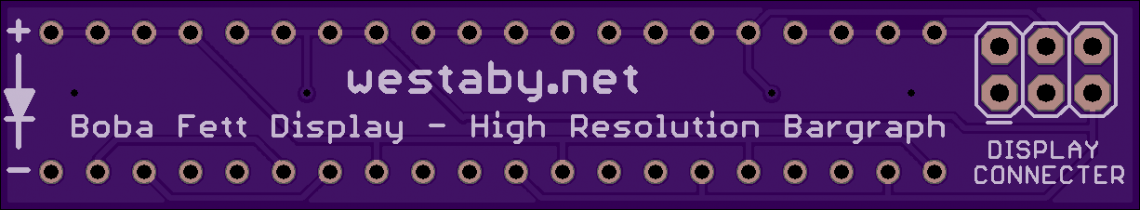

Upgraded Boba Fett Chest Displays

Dec 2020 brought new episodes of the Mandalorian which blessed fans with the reappearance of Boba Fett and his faithful armor. The chest display refresh gets me excited. Instead of a blocky bargraph lightshow, we get a fully animated larson scanner! Remember larson scanners? Classic sci-fi light animation that sweeps back and forth, night rider, bsg cylons, etc. My previous boba fett chest display circuit is not wired for a fully animated bargraph. The ESB and ROTJ style animations both used 5 animated blocks above the character displays. So I designed the bargraph to be run on 6 wires. Five control wires from the chip and one common for ground.…

-

Ammo Counter Assembly Instructions

DIY assembly guide for the ammo counter. If you ordered an unassembled circuit kit, this is the instruction page for you. Assembly order is from the center outward to minimize solder bridges. Keep some solder removal braid handy to remove any bridges between pads. BACK OF THE PCB Install the IC, making sure to orient with pin1 indication on the PCB Install the three resistors. 2x 10k on the bottom 100 ohm on the top Install the LEDs and bend into position to match your install location. LED on top center position (unmarked) LED on bottom marked position. Note: The LED polarity is not marked on the board. See the…

-

Supernatural EMF Reader

This is a summary post of my finished “revision 1” EMF Reader from Supernatural. For revisions 2 and 3, please email me for the latest instructions. Below you will find the following sections: Description and Pictures Part List Rough Step by Step Build Instructions Hello Future Reader! This guide is outdated as of 2018. If you purchased a kit from me, you have the 0718 revision. Watch this youtube build video instead of following the guide on this page.https://www.youtube.com/watch?v=ce4PJZl9T2Y&t=1s&ab_channel=DustinWestaby Kits for sale! https://westabyelectronics.com/store/shop/ Description and Background: The EMF Reader in Supernatural is an excellent project for people like me that have some electrical knowledge. What I did was design a…

-

Cortana Dog Tags

In preparation for Halo 5, I am proud to announce the availability of Cortana Dog Tags! If you haven’t seen the trailer yet, check it out here~! The Dog Tags are in the store under Blank Cortana Circuit. Select the option to add dog tags and you will get a custom engraved dogtag, chain, and a eagle sticker! Updated July 6, 2013: Wow, thanks for the enthusiasm everyone. Cortana dogtags are sold out, there is a 3 week wait on the next batch. Click images for high res.

-

New Sound Options in the Store

I often get asked about offering sound functionality in my prop kits that I sell. As demonstrated by my energy sword design I had a solution for sound, but it was not a solution that I could extend to my cheaper kits. Sound is hard, not just hard but expensive. Till now. Introducing the 300 second USB recording module from <a href=”http://www.electronics123.com/300-second-usb-recording-module.html”>electronics123.com</a>. I have fully inregrated their sound module into the Backlit Ammo Counter offered in my store via an adapter circuit. The sound module can also be used stand alone, but you do not need me for that, go buy one from Electronics123! They are good folks. The need…

-

Cortana Prop Circuit

Project is a cortana prop. Partnered with James Hodson and friends to complete. My portion is complete. Have a circuit board here that is the size and shape of the Halo Data Crystal (the thing that can contain an AI such as Cortana). What is a Data Crystal Chip? Please see the Halo Wiki [halo.wikia.com]. Feature set: Circuit board is designed to look like a naked “cortana” data chip. Board can be placed in a molded outer shell to be more accurate. More details to come. Compatible with multiple power sources depending on final usage: LiPo cell (internal shell design) Alkaline (wired to slot connector) USB (wired to slot connector)…